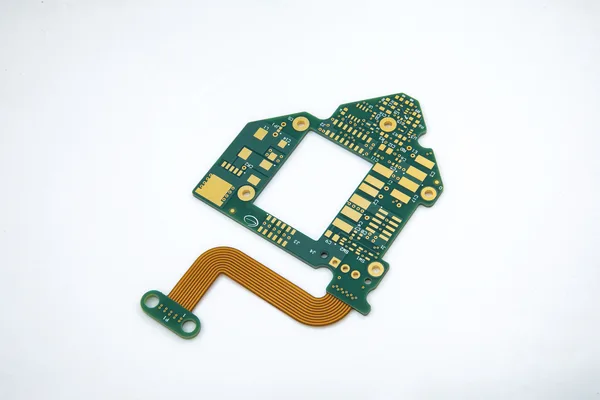

Flex PCB is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. It has the characteristics of high wiring density, light weight, thin thickness and good bendability. Flexible circuit is a technology developed by the United States for the development of aerospace rocket technology in the 1970s. It is a highly reliable and extremely flexible printed circuit made of polyester film or polyimide as the base material. By embedding a circuit design on a flexible thin plastic sheet, a large number of precision components can be stacked in a narrow and limited space, thereby forming a flexible flexible circuit. This kind of circuit can be bent and folded at will, light weight, small size, good heat dissipation, convenient installation, breaking through the traditional interconnection technology. In the structure of flexible circuits, the constituent materials are insulating films, conductors and adhesives.

Rigid PCB and flex PCB have both similarities and differences at the same time. For flex PCBs, rigid PCBs are more widely used. Because rigid PCBs appeared earlier, most of the design elements of rigid PCBs have been applied to the design of flex PCBs. So what are the differences between rigid PCBs and flex PCBs?

1. The current carrying capacity of the wire: Compared with the rigid PCB, the heat dissipation performance of the flex PCB is relatively poor, so sufficient wire width must be provided. Due to the heat dissipation problem of the flex PCB, it is necessary to give extra width or spacing to the wires.

2. Shape: In general, a rectangle is selected, which can save the substrate very well, and there should be enough free margins near the edge. A sharp inner corner may cause tearing of the board. Therefore, the smaller wire width and spacing should be minimized as much as possible, and the transition must be as smooth as possible. Sharp corners will naturally concentrate stress and cause wire failure.

3. Flexibility: The flexibility of rigid PCB is of course not comparable to that of flex PCB. For a large number of bending cycles, flex PCB has better performance.

Email: sales@fastlinkpcb.com

Phone: +86 - 0755- 23597570

Tel: +86 15171508318

Head office: 3A12 ,Floor 4, JinYuan Building B , Xixiang Rd, Bao'an district, ShenZhen , China

Factory Address: 3rd floor, Building D, Baishixia Industrial Zone, Jian 'an Road, Fuhai Street, Bao 'an District, Shenzhen ,china

Greetings! Very useful advice in this particular article! Its the little changes that will make the biggest changes. Thanks for sharing!